|

|

|

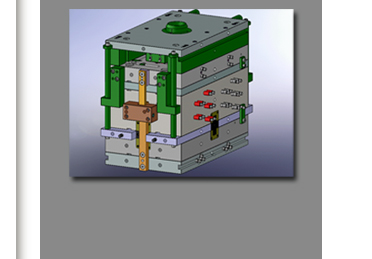

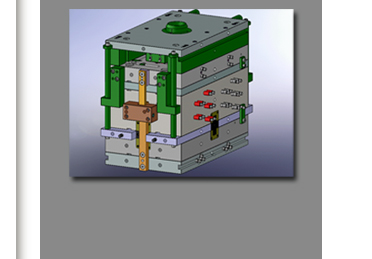

| APL is located in Northern Taiwan, which is well-known for experienced work force in wide spectrum of industrial disciplines, from computer & peripherals, consumer electronics, to power tools. Our tool makers have years of experience building tooling for Western customers, and understand Western requirements very well. We use tooling steel imported from Europe or North America. Most of hot runner systems we install are Moldmasters, DME, and Incoe – depending on customers’ specifications. Inch system tooling components are used on molds exporting to US. Original Progressive and DME components are available locally, if customers specify. |

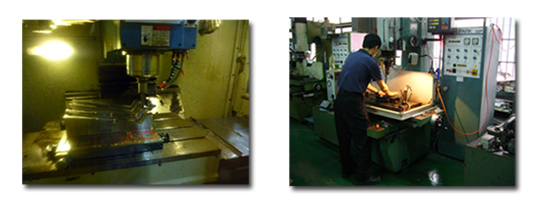

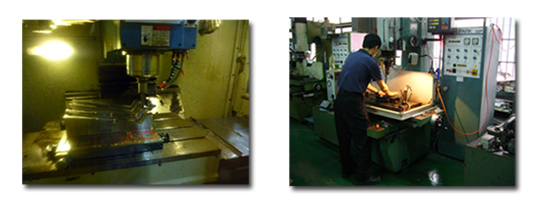

| We operate high speed CNC machining centers, CNC EDM machines, shape grinders, plane grinder, and conventional milling machines in house. A CMM is used to inspect parts and critical components. We have built molds up to 15 tons in weight, with capacity up to 20 tons. A good portion of molds we have built are for 850 tons, 1100 tons, and 1500 tons presses. Large tooling is one of our strengths. |

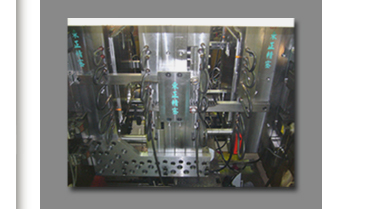

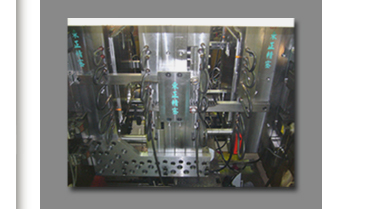

| Over the years, we have accumulated extensive experience building Gas Assisted Injection tooling. We have good knowledge on both PEP (with overflow) and conventional gas assisted processes. Handles, covers, and steering wheel molds are among the gas assisted injection tooling we have built. |

| Our strong engineering background enables us to manage customers’ projects in professional and efficient manners. We anticipate customers’ needs, and sometimes we react even before customer’s request. Excellent communication skills allow us to seamlessly work with customers oversea. Time zone difference becomes advantage in moving projects forward non-stop 24 / 7. |

|

|

|

|

|

|

|

|

|

|

|

|

|